Remember the Coffee Bar project we started in early 2013? Here’s where we left off. We took an unused wall in our dining room, built Ikea cabinet bases, and added a temporary wood counter top. Continue reading “Coffee Bar – Progress Report”

Ding-Dong

Last summer, while at Canadian Tire, El Granto picked up a doorbell cover that was a bit more fitting for our house. Our old one was basic and worked just fine, it was just a bit boring. Continue reading “Ding-Dong”

Custom Framing Mats

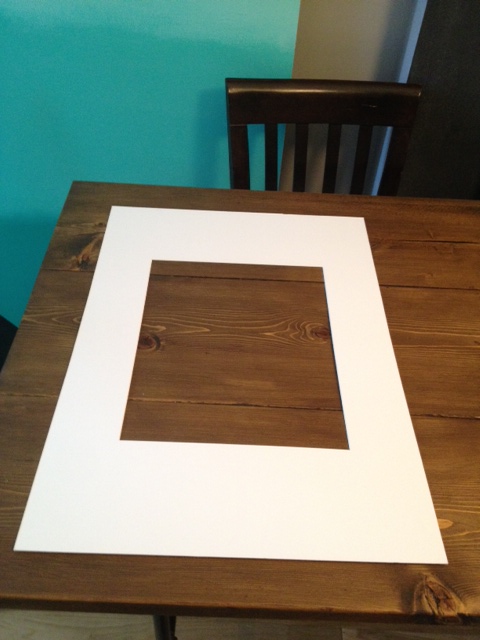

Have you purchased any Ikea (or similar) frames only to have the provided mat be completely the wrong size for your art? You could go to an art or framing store and pay (heavily) for custom cut mats, or if you’ve got a few dollars and some time and patience you can do it yourself.

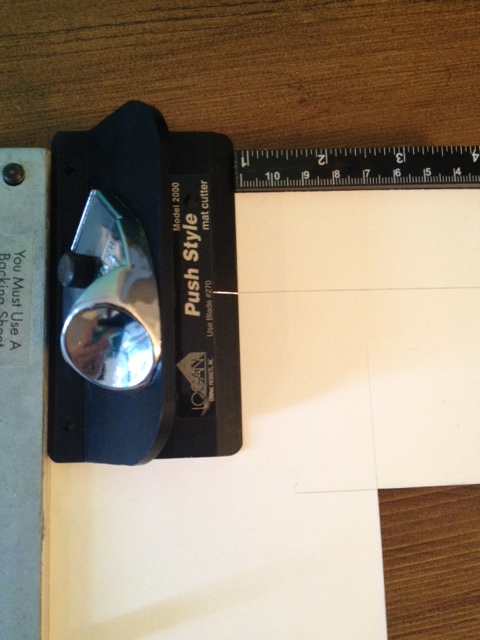

Back in my art school days, sick of trying (and failing) to cut mats with a straight edge, I broke down spent $50 of my poor ass college budget on a mat cutting kit. I then proceeded to cut all my art school project mats, as well as did a pretty handsome black market trade in cutting mats for my fellow students.

That (old battered) mat cutting kit still gets used several times a year, and has paid for itself many times over. If you are in need of several mats cut (doing a gallery wall any time soon?) If so, this may be the tool for you. Let me show you how it works.

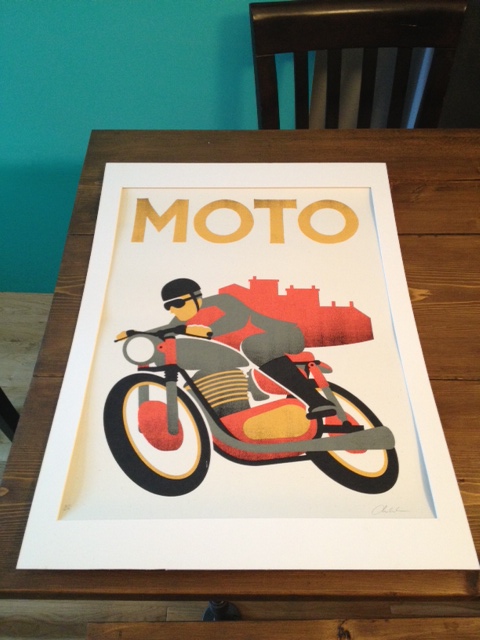

A few weeks ago we purchased a beautiful print from a great local shop Town Moto. This vintage inspired motorcycle gear shop is one of El Granto’s favorite places. They have great gear & accessories as well as an in house design & print shop. They produce some beautiful motorcycle themed prints, and we brought a purdy new Moto print home. The print is gorgeous. Its printed on a lovely heavy paper, and its signed, stamped and numbered. A print like this needs to be presented in a way that equals its awesomeness. So I went frame hunting in the basement and found a great big Ikea Ribba frame previously used for an old highschool drawing. I ousted the drawing from its frame and stole the mat to use with the Moto print.

Problem is, the mat hole is MUCH too small for my print. The easiest thing to do here is flat mount the print, but that doesn’t look as nice.

So I got out my mat cutting kit and set to work.

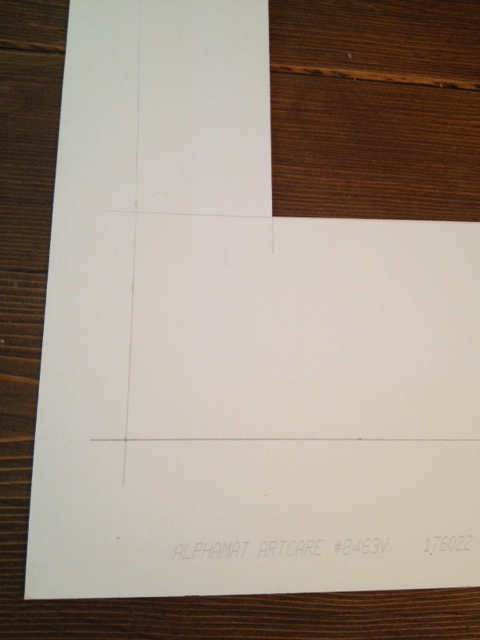

You need to figure out how big you want the new mat hole to be, and you need to draw the location of the new hole on the back of the mat so you can cut it. There are several different ways to do this. We wanted our print centered, so we did a bit of math (minusing the size of the new cut hole from the overall size of the mat to figure out how far from each side the cut hole needed to be.) Measure twice, if not three times before you cut, its easy to go astray especially if you’re dealing with 16ths of an inch etc. If you’re having problems with this step, feel free to ask questions and I will try (as best I can!) to explain in greater detail.

Place the mat (still upside down) into the mat cutter, and align one of your lines to the straight edge of the cutter.

Now starting at the bottom of the mat, place your cutter onto the mat, matching up the starting line on the cutter with the corner of the intersecting cut line. Push the blade into the mat, while holding the straight edge steady, and push the cutter along the straight edge, stopping at the top line of your cut hole. The key to this step is using a steady hand and pressure. Proceed to do all four sides of the mat, and ta da! Beautifully cut mat.

Now insert your print, attach the back and hang your professional framed print on your wall.

*If my instructions are confusing, let me know. This may be a situation where its easier explained by a video tutorial*

SOURCE LIST:

Materials:

Print – Town Moto

Frame – Ikea

Mat – Art Store

Tools Used:

Mat Cutting Kit (we have the Logan one, you can pick up a basic mat cutting kit for about $50 at art stores)

Measuring tape or ruler

Hammer & Nail (to hang)

Old Butter Knife (my secret for prying up the tabs on the back of the frame)

Difficulty Level (on a scale of 1-5):

Total Cost: $30

Dumpster Diving

What did you do this weekend? I spent my Sunday morning dumpster diving. Continue reading “Dumpster Diving”

Underestimating the Task

One of my faults is that I am a bit of a dreamer. El Granto is the realist, and I have my head perpetually stuck in the clouds. I think we can do anything we put our minds to (within reason). I will research the hell out of things, and have confidence I can do a task before setting out. I may not however estimate how hard (mentally or physically) the task may be. I have confidence in our abilities, and often tooo much confidence.

Here are some examples:

- I thought I could totes carry home two 8 foot lengths of 10″ tall mdf crown moulding on my own, walking, the 4km home from the lumber yard. Half way home I called El Granto begging him to come help me.

- I bought a kiddie pool for the dog and then had to carry it home (on my head) through busy streets during a heat wave.

- When I bought 2 4×8 sheets of mdf for the guest room board & batten, got the lumber yard to cut into into 2″ x 8′ strips, then tried to carry the 50 pieces of wood home on a borrowed moving dolly that had a mind of its own. It kept trying to weave into traffic, or jackknife and spilling the boards everywhere. El Granto had to steer it with a piece of wood like a gondola all the way home.

Last night was another example. A nearby house is doing a bunch of renos, and I noticed some bricks in the construction debris. I really want to make a backyard patio area with red bricks, so I stopped by and talked to the contractor and asked what they were doing with the bricks. Yesterday he gave us the all clear to come take as many bricks as we wanted. Awesomesauce! Now we just needed to get them home. El Granto tried to book a Zipcar van or truck, but as its the beginning of the month (and people are moving) there were no large vehicles available for the next few days.

Unperturbed by this, I convinced El Granto that we should go to the building site armed with a dolly, a granny cart, some milk crates and a bucket. We could fill up the containers with bricks, pile them into our dolly and cart and that we could make a few trips bringing bricks home. We loaded up the first cart worth, realized bricks weigh about 5lbs a piece, struggled home with them and swore to never do that again.

Hopefully this weekend we can convince bribe a truck owning friend with beer to help us shuttle the bricks. After they get home, and dry out, they will need some cleaning up, removal of mortar, and then hopefully they can become an awesome patio in the backyard this spring.

Have you taken on a task that’s too big (or heavy) lately?

Is it Spring Yet?

Last week I had an especially bad week. I went in for my second round of iron infusions, and this session was not kind to me. I came home with a fever and my whole body felt like it had been run over by a truck. I took a few days off and got some rest, and finally this week things are starting to get better. Continue reading “Is it Spring Yet?”

Pinterest Challenge – Restoration Hardware Shelf

We had so much fun doing the Fall Pinterest Challenge, that we jumped at the opportunity to do it again this time. The jist of the Pinterest Challenge is to stop just pinning ideas, and start creating. You’re supposed to DIY something from Pinterest. Whether it be a recipe, craft, home project etc.

I have a few pins over on Pinterest (only 2,555 or so…) so I had a good amount of things to choose from! I figured this was a good opportunity to knock something off the to-do list as well.

Our front door opens onto the dining room. We have built a coat rack, installed an Ikea wardrobe and we have a nice bench and mirror. The only thing lacking in the entry was somewhere to put your keys and mail, or to keep a coffee away from the dog while you’re tying your shoes pre-puppy walk. We don’t have a lot of space, so a traditional console table was going to be too big.

Here is our inspiration:

Source: restorationhardware.com via Kristen on Pinterest

If we love the shelf so much, why didn’t we just go buy one? errrr… The price for shelf + brackets was $240. Yep, for one lil shelf. Ouch. We just don’t roll like that.

So we made it (with our spin on it of course)

So how’d we do it?

Bought some 1″ gas line pipe (it matches our dining table!) from Home Depot.

Supply List:

- 2 – Floor Flanges

- 2 – 6″ Nipples (teehee)

- 2 – End Caps

Assemble them all together and this is what you get:

Now you need a shelf. We headed to the garage to check out what cool wood we had. We found some awesome worm eaten Butternut that El Granto had gotten for Christmas (yep we ask for building materials for Christmas). We loved the character of the butternut and decided it was the way to go.

We cut the piece of wood 28″ long, and trimmed the width to 5.5″. This would enable the wood to sit on the pipe, but inside the edges of the end cap and flange. We wanted to be able to see the cool bracket. You can easily make the shelf wider by resting it on top instead of inset.

Next up, after deciding on placement and height (centered on the wall and 40″ off the floor) we went stud hunting, and found that we could hit one of our brackets into a stud. So we marked out the placement.

After the holes were marked, El Granto screwed the bracket into the studs.

After the first bracket was attached, we attached the pipe nipple and used it to help us level the second bracket.

Next up we marked the second bracket, and used EZ Ancors to ensure the shelf would be attached to the drywall nice and sturdy.

We then attached the other flange to the wall with screws into the wall anchors, and then screwed on the pipe nipple and end cap.

We gave our wood two coats of furniture wax and laid it on top of the pipe, screwing the end caps against the wood to hold it steady. Oh and it’s nice and level!

TA DA! What do you think of our DIY Restoration Hardware Shelf & Bracket?

Make sure you check out all the other awesome Pinterest Challenge projects, check out the hosts blogs too!

Sherry @ Young House Love

Katie @ Bower Power

Megan @ The Remodeled Life

Michelle @ Decor and The Dog

SOURCE LIST:

Materials:

1″ Gas Line Pipe (2 flanges, 2 end caps & 2 6″ pipe nipples) – Home Depot

Butternut Wood – Gift

Furniture Wax – Home Depot

EZ Ancors – Home Depot

Tools Used:

Miter Saw

Sandpaper

Dish Soap (to wash the pipes)

Drill

Level

Pencil

Difficulty Level (on a scale of 1-5):

Total Cost: $16

Tin Ceiling Part 3 – The Reveal

Three weekends of sore muscles and standing on ladders are over, and we are now the proud (and tired) owners of a reclaimed tin ceiling. We first showed you how we prepped the ceiling, then how we prepped the tiles, today you finally get to see the finished product.

It was a bigger project than we anticipated. Anything where you’re working on the ceiling is exponentially harder. If we were to do it again, we would rent some scaffolding, as moving ladders around was a pain. We did borrow a work light from our neighbours, which was a necessity.

This is what the ceiling looked like before.

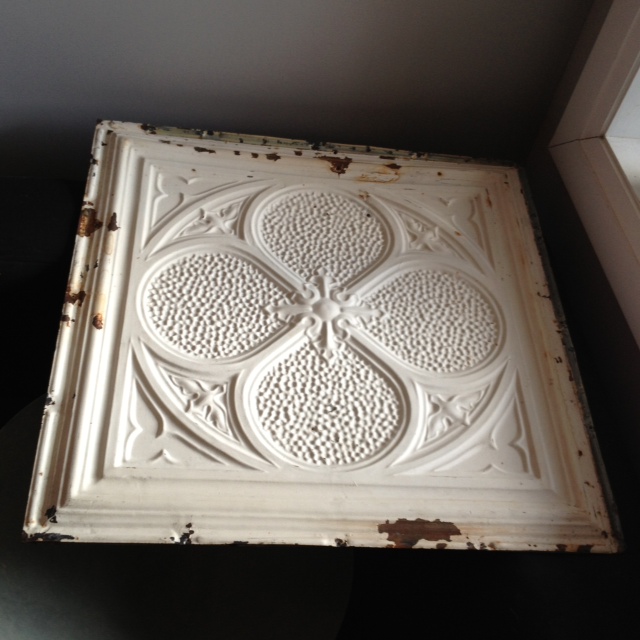

This is what we started with on installation day.

When installing the tiles you need to decide where you enter the room the most. The tiles overlap, so you want to make sure the edges overlap away from where you see the ceiling from most. We enter the living room from the hallway so we started the tiles at the corner farthest from the entryway (kitty-corner to the hallway).

The tiles overlap and have little notches where they fit in together. We figured this was enough to be able to line up the tiles properly, but once you’re standing on the ladder with the tile over your head, it’s much harder. We wish we had laid out a chalk line grid, it would have made the installation quicker and preventing one crooked tile that moved when I was nailing it. (arg)

After the first tile is up, we continued along that row to the end, then started the next now. Your arms get very tired, so this process ended up taking us two weekends to get done.

When we got to the middle of the ceiling we needed to deal with the electrical box. We had planned the tiles so that the light ended up in the middle of two tiles. We just needed to cut a half circle out of each tile around the light, and it should work perfectly. We traced the shape of the electrical box onto the tiles that needed to be cut.

Then headed out to the garage and El Granto cut the tiles with a metal cutting blade on his Dremel. (We could have used tin snips, but the curve is a bit tricky and the Dremel is waaaay easier.)

After the tiles were cut, we added an extension box onto our ceiling electrical box so that it would allow us room for the plywood and the tin tile. The box is easy to install (again the power is still OFF to this room!)

After the box was up we installed the cut tiles around it.

Then re-installed the light fixture.

We then installed the remainder of the tiles. The result is a very eclectic ceiling, but we love it. Some of the tiles are much more worn than others. We tried to make the layout look random, but still balanced. We would like to add some panel molding around the edges, but that will have to wait until we have access to a truck or van.

Without further adieu, here is the finished product.

The living room is starting to come along now. Next up, we need to trim out the tin ceiling, and swap out the light fixture for a more elaborate chandelier. A few more big projects and it will hopefully start looking more like the period building it once was.

SOURCE LIST:

Materials:

20 2′ Square Reclaimed Tin Ceiling Tiles – Aberfoyle Antique Market

3 4×8 Sheets of 3/8″ chipboard – Rona

Round Electrical Box Extender – Home Depot

Screws – Home Depot

Brad Nails – Home Depot

Clear Coat – Canadian Tire

Tools Used:

Drill

Compressor & Brad Nailer

Ladder(s)

Work Light

Chalk Line

Dremel

Difficulty Level (on a scale of 1-5):

(Really it deserves about a 3.5 it was just a pain as you are standing on a ladder working over your head)

Total Cost: $430

Tin Ceiling Part 2 – The Prep

How was your weekend? We knocked out our Pinterest Challenge project (check back Wednesday to see it!), we fixed a few nagging things around the house. (Our front door finally shuts/locks without jiggling the handle and shoving the door with your shoulder.) Unfortunately our doorbell still isnt working, but you cant win em all. Any doorbell experts out there that want to lend a hand?! (and/or any leads on where to buy Victorian Twist Doorbells?)

We have finished our tin ceiling project (full reveal tomorrow, I promise) but first I wanted to talk a bit about prepping the tiles for installation.

Our reclaimed tin tiles are 100+ years old, and covered in paint (which is most probably lead based paint.) The paint on our tiles had over the years seen some wear and tear. Some of the tiles were chipping, and the paint flaking off. Now the last thing you’re going to want is flaking lead paint falling from your ceiling, babies and puppies eating it and growing two heads so prep is important. (although two headed puppies would be cute)

*This is what WE did, we’re not experts, so please don’t take our story as gospel. Lead paint is a serious toxic substance, so ensure you contact your local government for how to safely handle & dispose of lead paint, and seriously consider calling in the pros*

To curb loose paint falling on heads, I took all the tiles to the basement, covered the floor in a plastic drop cloth, donned work clothes, heavy gloves, a respirator and safety glasses. I then proceeded to wire brush all the loose paint off the tiles. It was a bit of hard work, but worth it. I brushed quite aggressively ensuring all the loose paint came off. This process took a solid few hours. I then carefully folded the drop cloth in on itself, ensuring all the flaked off paint was trapped inside. I then sealed the drop cloth in a garbage bag, and its ready to head off to our city’s next hazardous waste drop off day. * DON’T PUT IT IN YOUR REGULAR GARBAGE! Lead = toxic! *

After the tiles were wire brushed, I headed to the garage and gave each tile two coats of clear coat. I then laid them out on every single surface of the garage to dry. I even gathered things for them to sit on; styrofoam pieces, boxes, bar stools, patio furniture etc. It looked like a very strange game of True American without the booze (any other New Girl fans out there?)

After the tiles are dry, its time to install (but you still have some prep left!) Some more paint MAY fall off when you’re installing the tiles. They are thin metal. and when you nail them up, they will flex and more paint may flake off (even though you carefully clear coated them!) SO, to ensure you don’t have lead paint all over your furniture, cover your floor & all surfaces where any paint may land, with more plastic drop cloths.

When installing, ensure you are again wearing eye protection (safety first kids!) and heavy gloves. The tin tiles can be sharp!

Geeze this post has been preachy. I expect I will make quite the nagging mother should I ever have children.

Staircase Inspiration

After painting the upstairs hall, getting started on our tin ceiling, and adding a new light to the staircase, the shabby beige walls of the staircase are looking pretty sad. Not to mention they are the LAST beige walls inside the house. (I have been mounting a war on beige as the entire house was beige when we moved in, no really outside and in, whole house was beige.)

The problem with doing anything to the staircase walls, is that they’re HUGE and TALL. Remember El Granto precariously hanging on the top of a ladder to hang the new light? Yeah…not fun.

I would really like to do something with high impact in the space. I am thinking a bold paint colour, wallpaper or a stencil. The entire main floor is a light grey, and the upstairs hall is white. I think this is the perfect place to inject something a little crazy.

Here are some ideas that I am loving right now, I just cant decide on one direction!

Source: designsponge.com via Kristen on Pinterest

I am loving the panelling with the pop of the runner!

Source: customizedwalls.com via Kristen on Pinterest

Houndstooth is a big fave in the Storefront house right now. Even the dog sports a houndstooth coat. Would it be too much on the staircase walls?

Source: matchbookmag.tumblr.com via Kristen on Pinterest

I love a wallpaper with some humour, and this dog print makes my heart smile.

Source: maxrollitt.com via Kristen on Pinterest

I LOVE the drama in this space!

Source: auctiva.com via Kristen on Pinterest

I am loving the blue in this wallpaper, but is it too close to the damask in our master bedroom?

Source: thezhush.blogspot.com via Kristen on Pinterest

This is a more classic style with the wainscoting + wallpaper. Is it fun enough?

Source: dorothydraper.com via Kristen on Pinterest

Now this is colour!!!

So what do you think I should do to the staircase? Bold colour? Crazy wallpaper? Or keep it more traditional and do paneling or a mix of paneling & wallpaper?