Happy Holidays from our family to yours! Wishing you all the best this holiday season!

xox Kristen, El Granto & Odin Continue reading “Happy Holidays!”

Month: December 2012

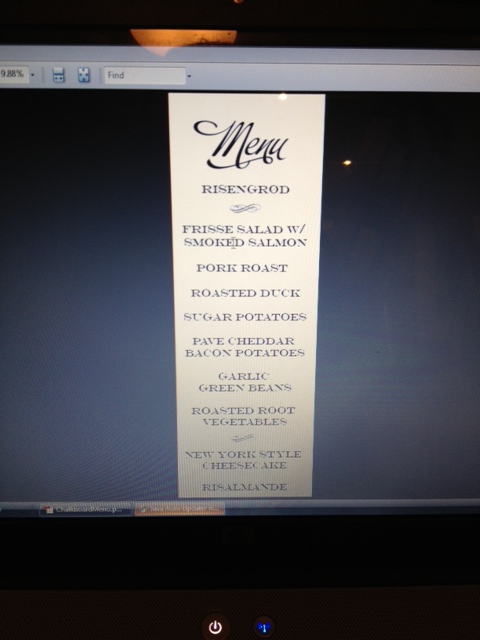

Chalkboard Menu

My family is rolling into town for the holidays in less than 24 hours. My to-do list is a mile long, I am contemplating giving up sleep to get it all done.

So it why on earth was I standing on a ladder drawing on our new chalkboard wall at 10pm? It was because I had a vision. I wanted a Christmas dinner chalkboard menu, and dammit I was gonna have one.

I had already planned out the menu, I just needed to decide how it was going to look on the wall. I decide to start small. While I love the amazing chalkboards on Pinterest, those are all done by chalkboard artists, and frankly the last time I touched chalk was writing lines on the blackboard in grade school. So I decided to set the bar low, and make a simple menu.

I laid out my type in illustrator on a canvas the same size as my wall.

Then I taped off the spacing on my wall, so I would know where each line of text was supposed to go, and so that the last line of dessert did not dip below the height of the table, so that everyone could see the menu. Once that was done, I started drawing.

I had the computer open beside me and I kept referencing my layout and tried to draw the “Menu” all pretty. Its not perfect, but I have absolutely horrid hand writing. For the actual menu I just wrote in my normal uppercase printing.

I don’t think it turned out that bad. I am by no means a chalkboard artist, but at least its legible. (Although El Granto thinks my “P” ‘s look like D’s. And that people will think we’re having “Dave Potatoes” for dinner…

Now all I need to do is clean the house, set the table, and cook all the food…

Chalkboard Wall

Our entryway, dining room and kitchen are all one great big open concept room. As soon as you walk in the front door you can see straight to the back of my kitchen. Its nice because the storefront window allows in a lot of natural light, and the open concept high ceiling space makes everything look a lot bigger than it actually is. Since moving into the house we have done very little to the main floor. The main reason being that anything we did would either cost a lot, or impact the whole main floor (i.e. we have one 60 foot long wall that runs from the front door to the back door, going through every room on the main floor except the powder room. So you cant just paint the kitchen or the dining room, you literally are painting the whole first floor.)

We have big plans for the space, we want to create a coffee bar in the dining room, replace the sink, faucet and countertop in the kitchen (and backsplash if I get my way). We just made a new dining table and bench. I have some art projects in the design stage, and a lot of projects for the livingroom.

In the interim I wanted to get the dining room ready for my holiday guests and for Christmas dinner. There is a chimney wall that juts out in the kitchen (see it behind the table in this shot).

I decided to give it a bit of a focal point, and paint it with black chalkboard paint. That way I can feature a menu board for dinner parties etc.

To start out I sanded down the wall to remove any imperfections and to make it as smooth as possible. Then I coated in one coat of primer.

I sanded the primer than applied one coat of chalkboard paint. I started to get a bit worried at this point as it didn’t cover well at all…

After a second coat it was started to look much better, but it still needed at least one more coat. I sanded at this point to try to make it as smooth as possible (chalkboards work best when they super smooth!)

So after sanding and a third coat of chalkboard paint I was starting to get the result I was looking for.

After this I gave it one more sand and what I thought would be the final (4th) coat. However after it dried it was even rougher than before. Eep! So once again I sanded and sanded and sanded some more then I painted a coat sideways instead of up and down. After that, I sanded and painted two more coats. Yes that’s right, if you’ve been counting you’ll know that we’re up to seven coats of paint. At this point I still wasn’t convinced it was smooth enough, but gave up because I had had enough of this project…and i deemed it “good enough”. Having never worked with chalkboard paint before I am not sure if I was just being anal retentive, or if you can actually get a perfectly smooth effect on a wall.

Once it had dried for three days, we covered the whole wall in a coat of chalk (rub the side of a piece of chalk over the whole wall.) Consider this like seasoning a cast iron pan. Then rub off with a dry cloth, and you can use your chalkboard wall. Just don’t wipe it with a wet cloth for at least a week.

Check back tomorrow to see how I designed my Holiday Chalkboard Menu!

***UPDATE*** Here’s the Menu

SOURCE LIST:

Materials:

Rust-oleum Chalkboard Paint in Black – Canadian Tire

CIL Primer – Home Depot

Tools Used:

Paint brush, tray & roller

Difficulty Level (on a scale of 1-5):

Total Cost: $20

Last Minute Man Gifts

It’s days before Christmas and you have nothing under the tree for the men in your life. Why are men always so hard to buy for? It’s because when they want something, they go out and buy it for themselves. New smartphone? They have it the day it comes out. So what do we do? Buy them socks or blindly guess what they want. So here are my fail-safe last minute gifts for men. Continue reading “Last Minute Man Gifts”

Christmas Menu

We are hosting my immediate family for Christmas dinner this year. It should be a fun night filled with food, drinks and laughs. Continue reading “Christmas Menu”

Outdoor Planters

We made a large planter box for our cement front yard a few years ago. It served two purposes, it gave some greenery to an otherwise paved front yard and secondly it made people aware that it was our property not just a very large sidewalk, and thus in turn got them to stop walking right by my front window. It has worked quite well. We still get the odd person who will take the route up by our window, but generally it gives us much more privacy.

In the spring I have bulbs planted and get lovely spring flowers. In the summer I plant bright annuals which last mostly into the fall.

For the holidays (and the rest of the winter) I like to have some fresh greenery and a little bit of rustic winter charm. So this year I hit up a local grocer who sells Christmas trees and greenery. I purchased about 5 bunches of assorted greenery, and my Mom and I set to decorating the planter. We also had some left over garland from another project. We’re not florists, and our only mission was to give it a bit of height and fullness. I also purchased a package of pine cones at my local dollar store, hot glued them to coffee stir sticks, and tucked them in here and there.

We also did a small urn under our mailbox by our front door.

So even though we don’t have Christmas lights up (we don’t have any outdoor electrical boxes!) it still looks festive. That combined with a wreath on the front door has our storefront in the holiday spirit.

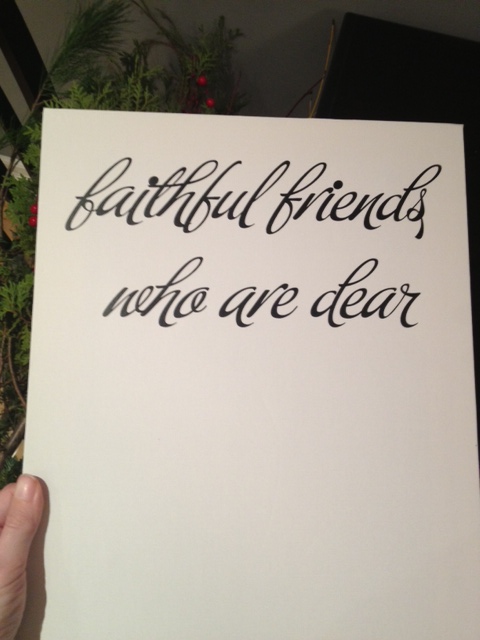

DIY Holiday – Chrismas Carol Art

I have taken to decorating the little shelf over our front hall coat rack as a would-be mantle. It got decorated for Halloween, Thanksgiving and now its getting a little Christmas cheer. My local dollar store sells 12×16 stretched artist canvases for the low price of $2. They also sell $1 acrylic paint. I figured this was an excellent excuse to make some inexpensive holiday art.

While singing Christmas carols at my desk one day (yep I’m one of those holiday spirit kinda people) I decided that my art project should revolve around Christmas carols. I promptly went home and laid down some type in Illustrator of the lyrics “Faithful friends who are dear to us, gather near to us once more”. Hopefully our visiting friends and family will feel welcome this holiday season!

After I was happy with my type layout and font selection, I cut out the type using my Silhouette SD onto adhesive vinyl. If you don’t have a silhouette, you can pick up alphabet stickers from craft stores, or you can cut your own out of adhesive material. After my stickers were cut, I removed the excess vinyl (called weeding) and transferred my stickers using transfer paper (it’s sticky paper which pulls off the vinyl from their backing, then you place it where you want your stickers and apply using a credit card.)

After my stickers were adhered I took a look and loved it just the way it was! I know, lazy me! If you want to do it right, paint around the edges of the stickers with some white acrylic paint. You do this so that if any of the paint bleeds under the stickers, its white like the canvas so it wont be visible. After it dries, coat the whole canvas in 2 coats of black, red or green paint.

After the paint dries, remove your stickers, and reveal the white canvas below. Or be lazy like me and just put stickers on canvas, then go drink some rum laced eggnog instead.

Where was I? Eggnog? Oops. Right. Project…

Then I placed it up on my mini mantle with a small artificial tree, candles, fresh greenery and a ceramic pear.

Materials:

12×16 Art Canvas

Adhesive Vinyl

White & Black Acrylic PaintEggnog for extra holiday cheer

Tools Used:

Silhouette SD

Paint Brush

Difficulty Level (on a scale of 1-5):

Total Cost: $2 ($4 if you paint it)

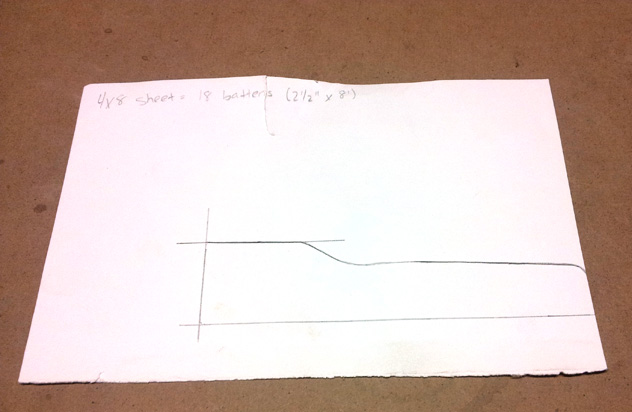

Woodworking for woodworking’s sake

I don’t typically think of myself as an old man. There’s only a few times that I do. One was just the other day when I told a kid (twenty-something) to get-the-f off my garage roof (He was fetching a football. It’s a silly expletive filled story). After doing so I felt so old I had to do something to calm my nerves. Some old man stuff. “Why not some wood working” I thought.

I have a pintrest board (yeah I know I know. Not typically a place for guys like me. It doesn’t see a lot of use.) that is absolutely FULL of things I want to make. I won’t link to it because I think a lot of it will end up being posted here at some point. Probably even before Christmas as I really enjoy making gifts for family and friends. It’s cheaper and it really shows you care when you can make something for someone that’s genuinely cool.

So my first adventure in woodworking was to create something functional and not too hard to make. I checked out my pin board and found the perfect item. The Nail Head Bottle Opener.

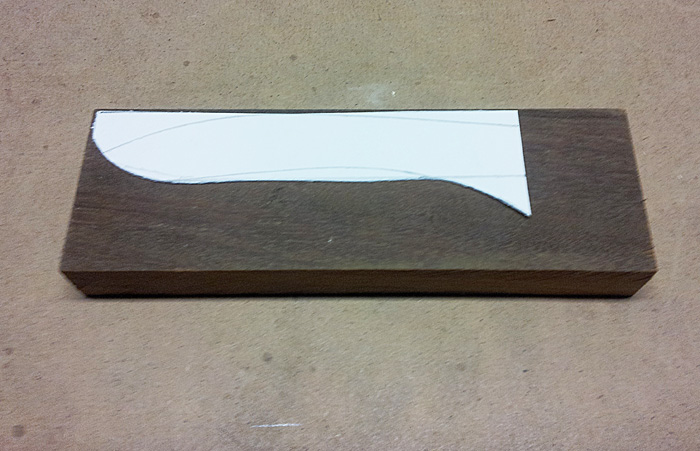

Wood… I need some nice wood… all I have is pine. Hmmm. The next door neighbors have LOTS of wood! And nice wood! Ipê Iron Wood.

I ended up securing a piece of wood from my neighbor Dietrich (on his birthday. Happy birthday! Can you give me a gift instead?!).

Enough story time. Let’s get to it.

I started by drawing the outline for the bottle opener on a piece of card paper that I had laying around in the garage. I modeled it somewhat off of a wire brush that I liked the handle shape of and modernized it a tad to fit with the feeling I wanted from the piece.

I then traced the outline on to a small piece of wood that I cut down to size with the miter saw and cut the general shape out with a jigsaw being careful to cut just outside the lines so that I had room to sand down in to the final shape I wanted.

Once the shape was cut it was time to sand. I started with a rough 60 grit paper on a palm sander and got the exact shape I wanted. This was also when I found out that our jigsaw doesn’t quite cut on a 90°. Darn. Sand away the angle. Once that was done I switched to a 100, 150 then 220 grit paper and sanded by hand. To get the curve near the top to feel just right I took the sand paper and wrapped it around some spare pipe so that I would get a consistent groove without too much hassle. Sand sand sand sand sand. Now sand more. Sand till your fingers are raw and the wood is buttery smooth.

I took the finished wood inside to the warm and applied and buffed 5 coats of finishing wax. Man did it pop after the wax!

With the wood all sanded and shiny I then set to bending nails. Kristen picked me up some special nails for this project specifically. I wanted nails with a large flat head that still looked nice. Luckily the rep for the nail company was visiting HD that day and was able to show her to the absolute perfect ones. I bent 4 nails in the bench vice using a hammer and a rag wrapped around the bottom of the nail before I got the result I wanted.

I had a magnet laying around that I wanted to put in to the opener to catch the bottle cap so I carefully drilled a hole that was purposely a little too small for the magnet to fit in to then I hammered it in to place using more rags to protect the piece from getting marred by the hammer. The magnet will stay in place strictly through friction.

I then clamped the opener in the vice (more rag protection) and drilled a hole in the top just big enough for the nail to slip in to easily. I didn’t want to force the nail in by just driving it in as it could split the wood OR mar the nail leaving the whole piece useless. I applied a generous amount of wood glue to the nail and slipped it in place cleaning up any that splooged out with a wet cloth.

Applied and buffed one more coat of wax and I’m ready to pop bottles!

Making this bottle opener was actually quite simple. I will however drill the holes for the nail and magnet BEFORE waxing next time as drilling requires more sanding.

Working with a strange wood was a great learning experience. Hard woods take longer to cut and work with and you have to be careful of burning or scorching the wood. During the drilling of the nail hole I was glad I don’t have a smoke detector in the garage (on the to do list for sure) but there was a lot of smoke.

SOURCE LIST:

Materials:

Ipê Iron Wood – Dietrich the friendly neighbor

3″ Common Framing Nails – Bright Finish – Home Depot – $4.00

Pretty magnet – Repurposed (I have since picked more up at Lee Valley – 3/8″ diameter 1/10″ thickness – $0.46 each)

Minwax Paste Finishing Wax – Home Depot – $9.99

Tools Used:

Drill

Jigsaw

Miter Saw

Palm Sander

Sand Paper

Bench Vice

Hammer

Difficulty Level (on a scale of 1-5):

Due to time and patience.

Total Cost: $4 Only bought the nails!

DIY Pipe & Wood Bench

BIG Milestone today kids! This is our 100th post!

So we made the dining table, then we finished the table, and now we’re making a quick and easy (and cheap) bench to go along with it.

Left over from our table offcuts, was a 2×12 piece of wood just about 6′ long. El Granto decided to surprise me and make a matching bench to go along with our table. The bench will add a lot more seating (you can squeeze a truck load of people around a bench when necessary.) It also reduces the amount of chairs we have to have, and a bench can be tucked close into the table and not take up a ton of room.

Here’s the shopping and cut list for what you need to make a 68″ long, 11 1/2″ wide and 18″ high wood & pipe bench.

Shopping List

(leftover 2x12x6′ from the table project)

2 – Premium 2×4’s

2 – 3/4″ Flanges

1 – 48″ precut piece of 3/4″ black pipe

8 – 1″ wood screws

Cast Iron Square Nails (Optional)

Wood Cut List

1 – 2x12x68″‘ spruce

4 – 2x4x16 1/2″

4 – 2x4x6 1/2″

Pipe Cut List

You don’t need any custom cut pipe. Use your 48″ precut piece as is. Woot!

Assembly

Pre-sand your pieces of 2×4 (these will be the bench legs, and once assembled are a bit more of a pain in the ass to sand.) While you’re at it, sand the bench top as well. Start at a 60 grit or so, then work your way up to 220.

Assemble bench legs using your attachment method of choice. We decided to go with the Kreg Jig pocket hole system, but you can easily use dowels & glue. El Granto got a bit carried away in the assembly process, and forgot to take any pics until it was all done (oops!).

Here’s a shot of one set of legs, where El Granto is adding some decorative square nails. You can see how we used the pocket holes to attach the top support piece, we also used pocket holes below the bottom vertical support piece. The bottom support piece is vertical because we are going to attach our pipe cross beam there.

After the legs are assembled, attach the flange to one set of the legs, then attach the pipe and the second flange and screw the other flange to the other set of legs.

Flip the bench top upside down, and place your upside down legs on top, and screw legs into bench top using 2 1/2″ screws.

After the legs were attached, we took the bench inside to start the finishing process. We stained and oiled it to match the table.

We now really need some new chairs. In the interim, I think I will give the ones I have a coat of paint. I am leaning towards turquoise or red. Eventually I would really love some Tolix chairs or some Emeco navy chairs. The dining room also desperately needs some high impact art, as does the area over my kitchen cupboards.

SOURCE LIST:

Materials:

2 – Premium 2×4’s – Home Depot

1 – 3/4″x4′ black pipe – Home Depot

2 – 3/4″ Floor Flange – Home Depot

2×12 spruce – Rona

1″ wood screws – Home Depot

Varathane stain in Chocolate – Home Depot

Varathane wood conditioner – Home Depot

Pure Tung Oil – Lee Valley

Square Nails – Lee Valley

Tools Used:

Miter Saw

Kreg Jig

Measuring Tape

Hammer (for decorative nails)

Drill

Difficulty Level (on a scale of 1-5):

Total Cost: $16 (bench top wood, and finishing materials were left overs from the table project)

DIY Pipe & Wood Table Pt 2

If you missed it, we built a Wood & Pipe Dining Table, check it out here.