I’m so excited to share today’s project! It’s something I’ve wanted to make for over a year. When I first started talking to Jeremy at Buddy Rhodes about making our concrete counters, he told me to take a look at his portfolio of work. He wanted me to be inspired by the awesome stuff you could do with artisan concrete, and to brag a bit about how awesome he is.

One of the first projects of his that caught my eye was a series of concrete clocks. I sent him an email saying something along the lines of “omggggg I need to make a clock!” said in over excited girl squeal. He kept saying clocks were easy, and after we pour our kitchen including a badass one piece waterfall countertop, I will be able to make a clock in my sleep. But clocks seemed like such a big project. So much so that I never tried to make one. Then a few buckets of Buddy Rhodes 10lb artisan mix showed up at my door a few weeks ago, with a few curse words gentle push from Jeremy to get off my butt and make something. So I made this:

DIY concrete clock! It was so easy. Really truly so easy. Here’s how I did it:

Milwaukee M18 Hammer Drill + Mixing Paddle + Small Bucket + 10lbs Buddy Rhodes Artisan Mix

I sourced a mold in a shape I liked. I went with a $1 Christmas Snowman cookie tray from the dollar store.

The only other item I used for my mold was an empty plastic screw container. It was the perfect size for a inset in the back of the clock for my clock works. Note, you don’t even have to do this, your clock works can totally stick off the back of your clock.

I mixed up a small batch of the BR mix, with a teaspoon of coal coloring & a dash of water reducer. This is also optional. The water reducer will let me put less water in the mix, but still get a nice workable mix. I used coloring to get a grey color, but the BR mix is bone white, and If you don’t want to tint it, you don’t have to. The mix has no large aggregate (gravel) so it can be made into tiny or thin molds without issue. I mixed up my concrete with a paint mixing paddle from the hardware store. My Milwaukee Hammer Drill made quick and easy work of mixing.

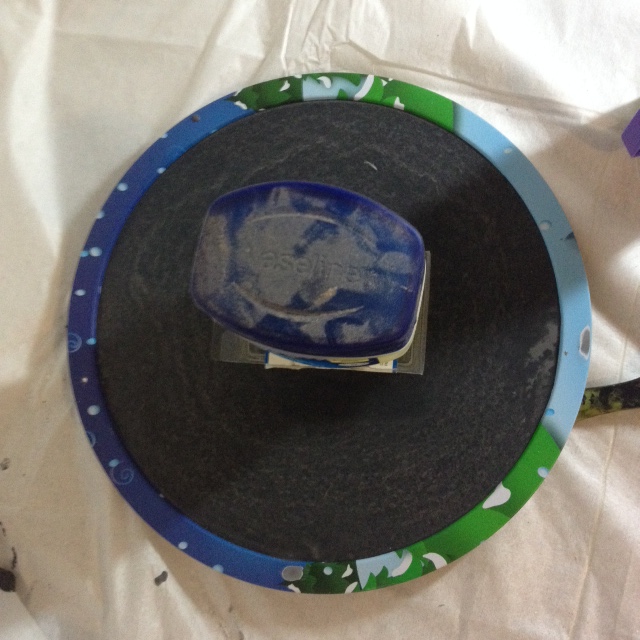

Once it was to the viscosity of a milkshake, I poured it into my mold. I filled it 3/4 full. I inset in the screw container, and weighed it down with a jar of Vaseline (Vaseline can be used as a mold release, so I had it on hand. I’m not a creepy weirdo who keeps Vaseline in their basement workshop for no good reason).

I gave it a shake to level everything out, and a bit if vibration from a palm sander. I covered with plastic sheeting, and left to cure in our nice warm basement.

I had a bit of extra mix left over, and I also had some simple silicone molds nearby, so I poured the excess in to them. (I will show you how they turned out next week.)

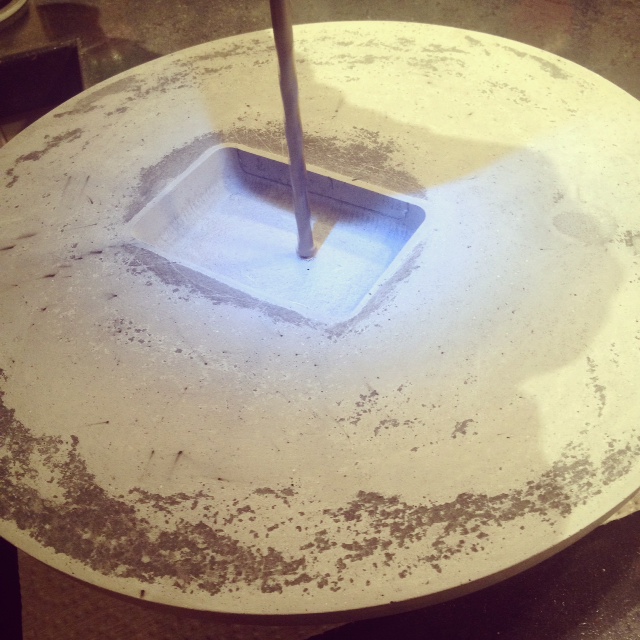

The next day I unmolded it by very carefully flexing the tray until it popped out. This is what it looked like after unmolding.

It was almost perfect, except you could just slightly see the outline of the snowman design. To remedy this I lightly wet sanded with 400 grit diamond hand sander. In hindsight, I would have not sanded. The finish was even more perfect before sanding, and I don’t think you would have seen the snowman after a quick buff. Where I did need to sand however was the back of the clock. I evened things out and took off any roughness around the edges.

Next we drilled out a hole for the clock works. Note, each brand requires a different size. We used one from Lee Valley, and it required a 5/16 hole. We purchased a masonry bit, marked the center of the clock and got drilling.

I applied four coats of Buddy Rhodes satin sealer with a lint free cloth. After the sealer dried, the clock & hands were quickly installed with the provided hardware (read the directions for your brand). My clock works came with a hanging attachment, which wrapped around the clock works. It saved me figuring a way to attach a hanger to a piece of concrete. I opted to not apply any hour indicators to keep it more modern, but adhesive ones are sold in the clockmaking isle at your local craft store. For my next clock I think I may just put one number on. Perhaps a three? You can also make your own with adhesive vinyl. If you’ve got a craft cutter, you can easily make anything you’d like. Heck, even make an Alice in Wonderland clock with wonky numbers. (Storing that idea for LATER!)

The clock has a nice polished concrete surface, in fact, it’s so polished its hard to photograph. I have tried the clock in a few places in the house. Here is is against the black wall of our powder room. I love the contrast.

The concrete surface is nice and uniform with a few tiny bubble holes where I could have given it a bit more vibration. Honestly, if it was any more perfect it would look like plastic, so I don’t mind the imperfections much.

Overall I’m very happy with the results, and am itching to make concrete clocks for everyone for the holidays.

SOURCE INFO:

Materials:

Clock Works $5.40 – Lee Valley

Clock Hands $1.95 – Lee Valley

10lb bucket Buddy Rhodes Artisan Concrete Mix – $18.95 (one bucket would easily make 3-4 clocks)

Buddy Rhodes Water Reducer – $25 (optional)

Buddy Rhodes Coal Coloring – $9.85 (optional)

Buddy Rhodes Satin Sealer – $45 (optional – this will last you for a ton of projects, we did our countertops and still have a bunch left over)

Tools:

Milwaukee M18 Hammer Drill

Bucket

Paint mixing paddle – Paint isle at the hardware store

Buddy Rhodes diamond hand sanding pads

Trowel for scraping bucket

Dust mask (wear during mixing)

Rubber Gloves (concrete dries out your hands)

Plastic drop cloth

Masonry drill bit (the size recommended for your clock works)

Difficulty Level (on a scale of 1-5):

Total Cost: $25

Disclosure: Buddy Rhodes sent me a sample of their new mix, with no obligation or compensation for me to post about it.